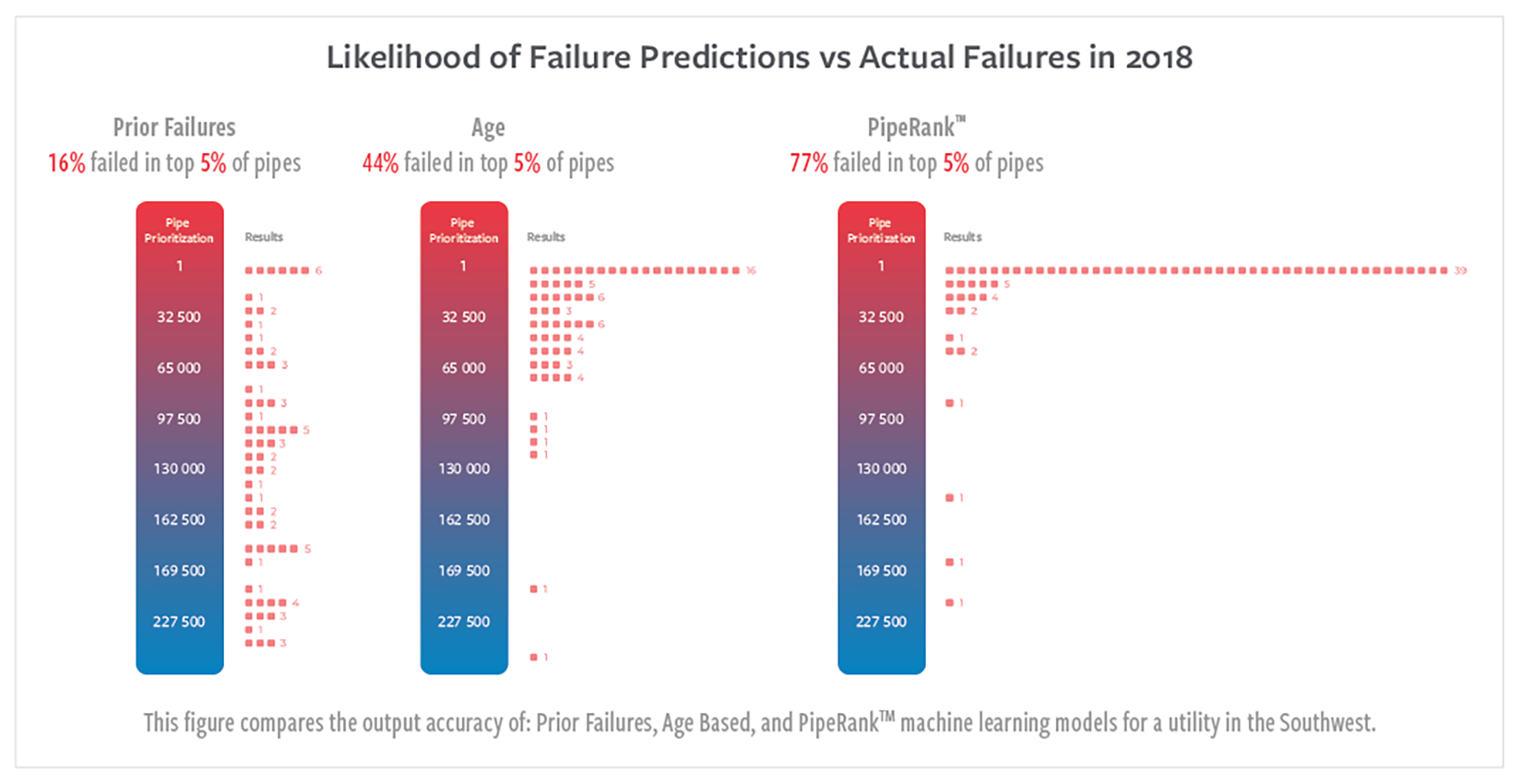

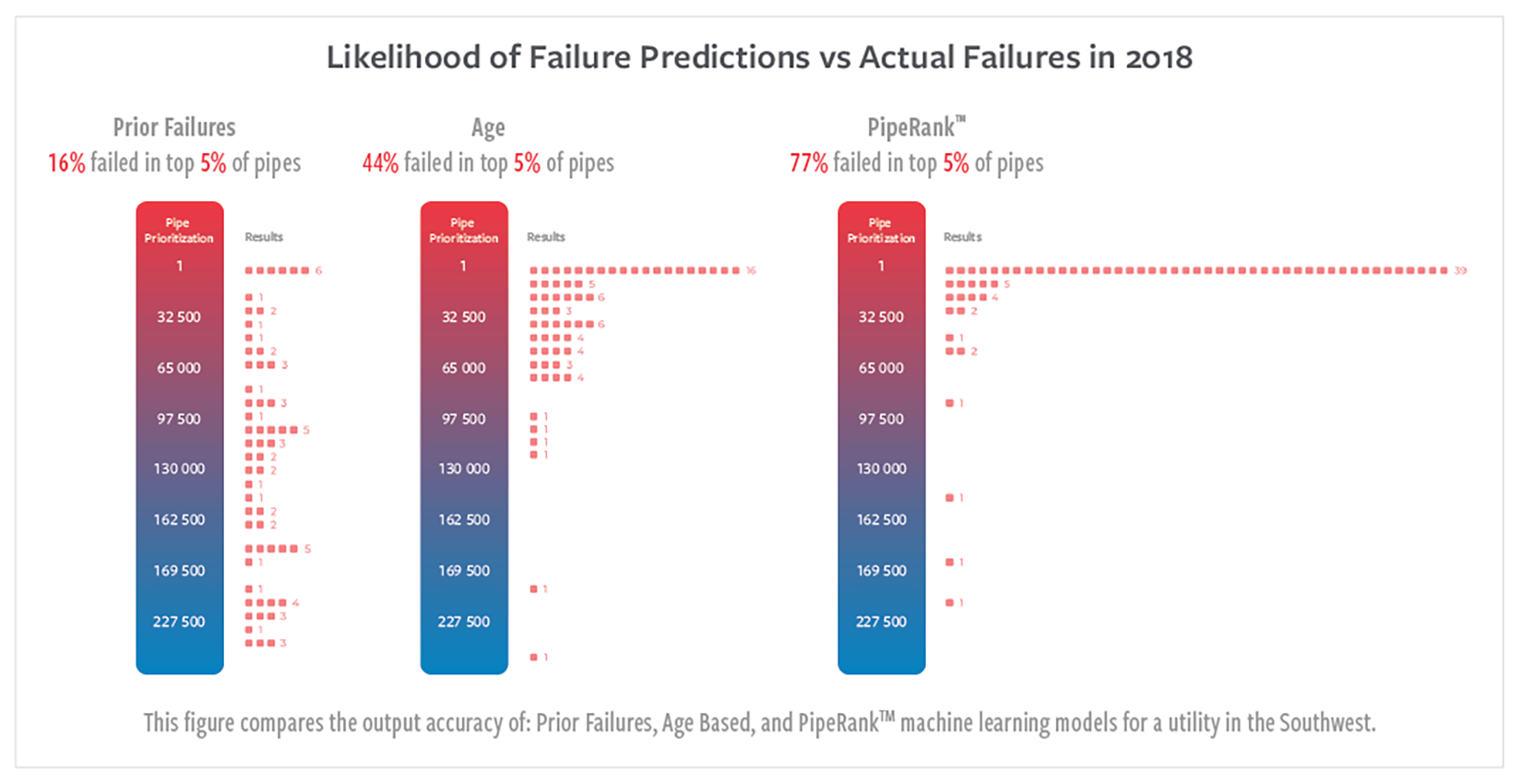

The figure below shows a comparison among Prior Failures, Age, and PipeRankTM machine learning model, for a utility in the Southwestern United States. In this example, each model was ran using available pipe construction, historical failures, and environmental information, and each model was used to prioritize all the pipe segments from most to least likely to fail. The red dots in the diagram represent actual failures in the year following the modelling analysis.

The PipeRankTM model correctly placed 77% of the actual pipe failures in the top 5% of pipe segments most likely to fail. This compares favorably to 44% for the Age Based model and 16% for the Prior Failures model. The ability to define and predict which pipes will fail offers exciting opportunities to manage pipe networks more efficiently with better levels of service.

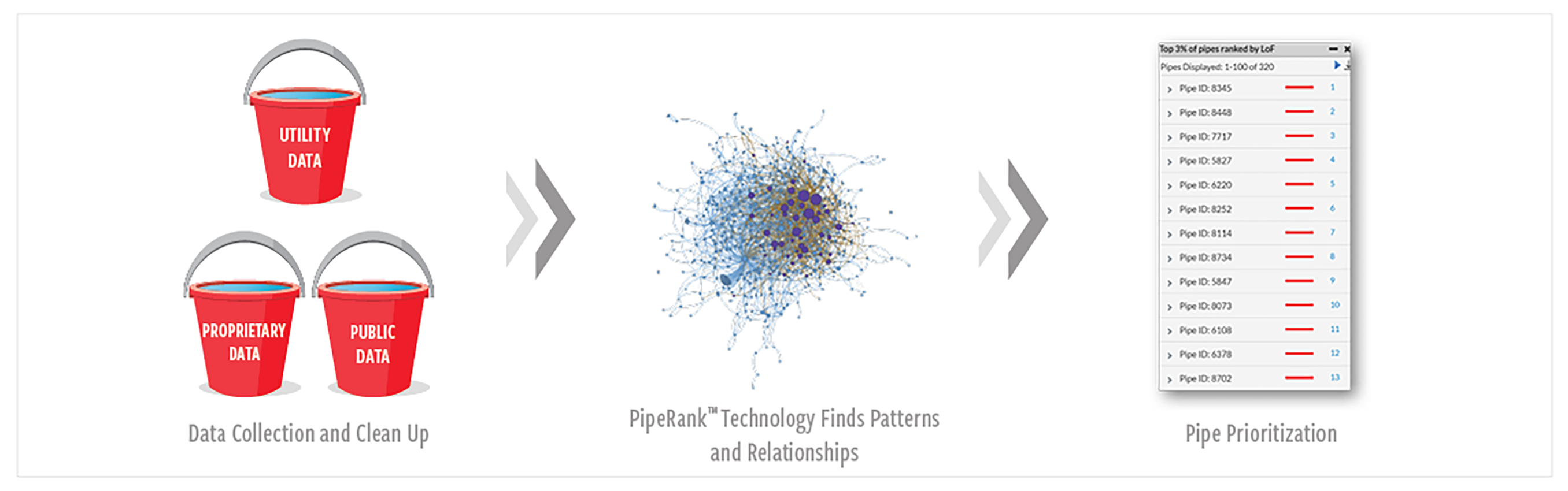

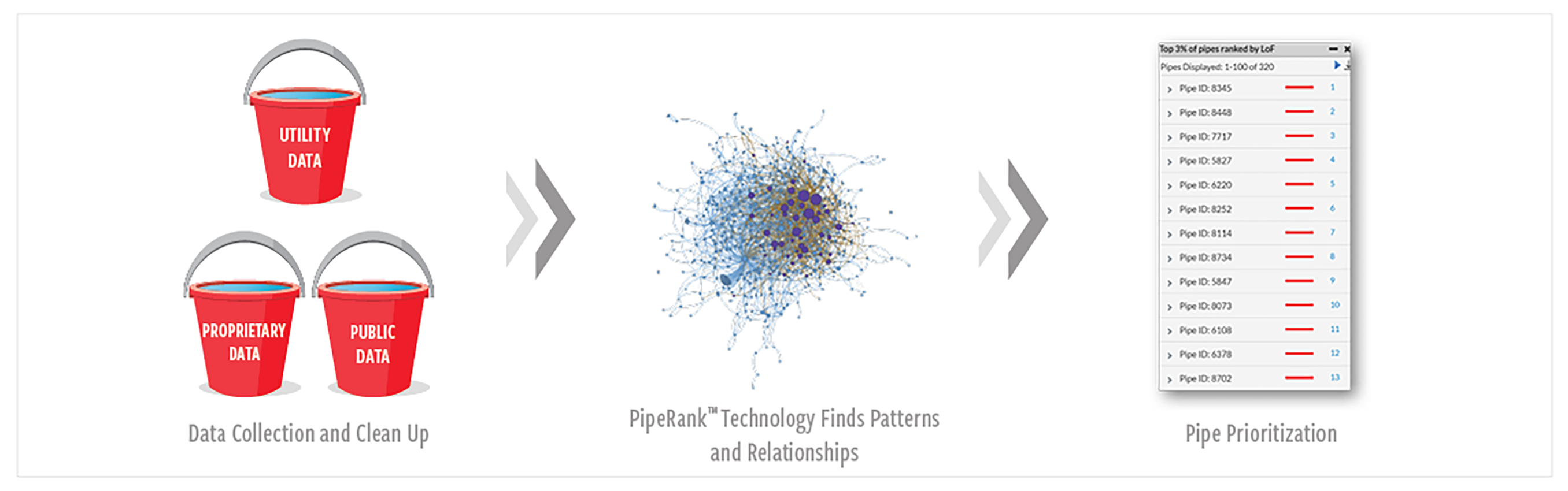

PipeRankTM technology pairs available pipe degradation factors with a proprietary machine learning model in order to prioritize every pipe segment analyzed by Likelihood of Failure. The datasets considered by the machine learning model includes pipe construction data such as: material, age, diameter, presence of a factory or field liner, as well as environmental factors such as soil, weather, and satellite data. Proprietary variables are also generated based on private data sources that have been shown to have positive predictive power for pipe failures in several utilities. The system can produce business risk profiles for 1-20 years, helping utilities reduce pipe failures, non-revenue water, and premature pipe renewal.